How to Maintain Your Industrial Scales for Long-Term Accuracy and Durability

How to Maintain Your Industrial Scales for Long-Term Accuracy and Durability

Blog Article

Discover the Perks of Utilizing Industrial Scales in Your Service Workflow

Incorporating commercial scales into your company operations offers a wide variety of advantages that can change your functional framework. From improving precision in measurements to improving total efficiency, these devices play a critical function in reducing waste and ensuring conformity with market standards. As services increasingly look for to enhance their procedures, recognizing the complex benefits of industrial scales comes to be crucial. What ramifications could these enhancements carry your functional strategy and profits?

Boosted Accuracy and Accuracy

Accomplishing boosted accuracy and precision in measurements is critical for businesses that depend on commercial ranges. These ranges play a vital role in different sectors, consisting of manufacturing, logistics, and food processing, where specific weight measurements directly affect operational performance and product high quality. Precise dimensions avoid costly errors, make sure conformity with policies, and improve client satisfaction by supplying items that meet defined weight needs.

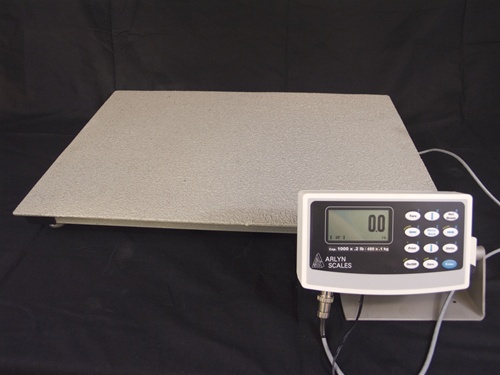

Industrial scales are designed to supply high degrees of precision via sophisticated modern technology, such as load cells and digital screens, which minimize human mistake and environmental factors that can affect readings. Routine calibration and upkeep of these ranges are vital to maintaining their performance, guaranteeing that they yield dependable data over time.

In addition, precise measurements promote better stock monitoring, enabling businesses to track stock degrees extra effectively and decrease waste. By utilizing industrial ranges with improved accuracy and accuracy, firms can maximize their production processes, ultimately bring about improved earnings. In summary, the combination of high-precision commercial ranges right into service operations is not merely an investment in devices yet a tactical approach operational quality and sustainability.

Boosted Operational Effectiveness

Industrial ranges substantially boost a service's operational efficiency by simplifying processes and decreasing time spent on measurement-related jobs. By automating weight dimension, these ranges decrease manual handling and the potential for human mistake, causing even more trusted and constant results. This automation permits personnel to concentrate on higher-value tasks, eventually boosting productivity and source allowance.

In addition, the assimilation of industrial scales with stock management systems allows real-time tracking of products and items. This ability lowers hold-ups in handling and makes sure prompt restocking, protecting against expensive downtimes. Companies can additionally much better take care of supply chain logistics, as exact weight dimensions help with optimal delivery and managing techniques.

In sectors such as manufacturing, food handling, and logistics, the capability to rapidly and properly measure weights can significantly impact throughput times. The efficiency obtained from using commercial ranges translates into quicker turnaround times, allowing firms to fulfill customer demands promptly and effectively.

Compliance With Sector Criteria

Just how can businesses guarantee they satisfy the strict needs stated by industry laws? One efficient technique is the combination of commercial ranges right into their operations. These scales are developed to give precise dimensions, which are important for compliance with different governing standards, consisting of those associated to weight, safety and security, and top quality control.

Accurate considering plays a pivotal role in industries such as food manufacturing, drugs, and manufacturing, where non-compliance can lead to significant financial losses and legal consequences. By utilizing calibrated industrial scales, services can guarantee that their products fulfill specified weight needs, thus minimizing the risk of charges or recalls.

Additionally, many commercial ranges are geared up with sophisticated features such as data logging and automated coverage, which promote conformity audits and regulatory evaluations. This not only streamlines the paperwork anchor procedure but additionally improves transparency in procedures.

Moreover, routine upkeep and calibration of ranges are important to promote precision and integrity. By prioritizing these techniques, companies can foster a culture of compliance, guaranteeing that they not only fulfill industry standards but additionally enhance their track view record as credible entities within their respective markets.

Cost Reduction and Waste Reduction

Acknowledging the effect of accurate considering on operational performance, companies can take advantage of industrial ranges to considerably minimize expenses and reduce waste. By guaranteeing exact dimensions, firms can optimize their product usage, stopping over-ordering and excessive stock, which directly contributes to set you back financial savings.

Furthermore, exact considering helps recognize inconsistencies in material delivery, enabling timely improvements and minimizing losses connected with perishing or misallocation. In industries where basic materials are expensive, such as manufacturing and food manufacturing, also slight inaccuracies can bring about substantial monetary losses.

Executing industrial scales additionally improves production processes by enhancing workflows. When materials are weighed appropriately prior to handling, it decreases the probability of rework or product remembers, which are damaging and costly to a business's online reputation.

In addition, by enabling better monitoring and analysis of product usage, businesses can apply and recognize inadequacies targeted improvements. This data-driven method not only fosters a culture of continual renovation yet additionally sustains sustainability campaigns browse this site by minimizing waste - Industrial Scales. Ultimately, the calculated usage of industrial ranges not only safeguards earnings yet likewise advertises responsible resource monitoring

Convenience Throughout Industries

The convenience of commercial ranges is noticeable in their application throughout a wide variety of markets, consisting of manufacturing, food processing, logistics, and pharmaceuticals. In production, these ranges make sure accuracy in product dimension, which is important for maintaining item top quality and minimizing errors. Their robust layout fits heavy lots, making them excellent for manufacturing facilities where big amounts of products are processed.

In the food handling sector, conformity with safety and security and top quality policies is extremely important. Industrial scales facilitate precise ingredient measurement, helping in consistency and adherence to health standards. In logistics, weight confirmation is vital for shipping and transport, optimizing tons circulation and guaranteeing conformity with laws regarding weight limits.

The pharmaceutical market likewise benefits significantly from industrial ranges, as they are vital for precise formula and dosage dimension. Precision in this field can straight influence client security and treatment efficacy.

Final Thought

Incorporating industrial ranges right into service procedures yields considerable benefits, consisting of improved precision and accuracy, improved functional efficiency, and compliance with market standards. The implementation of these ranges adds to set you back reduction and waste minimization, while their versatility enables application across various fields. Eventually, the utilization of industrial scales not just maximizes stock administration however also fosters a society of conformity, consequently enhancing market online reputation and consumer contentment.

Industrial ranges substantially improve a company's operational effectiveness by minimizing and simplifying procedures time spent on measurement-related tasks.Integrating commercial scales right into organization procedures yields substantial benefits, including improved precision and precision, boosted operational effectiveness, and compliance with industry requirements.

Report this page